Summarize:

.jpg)

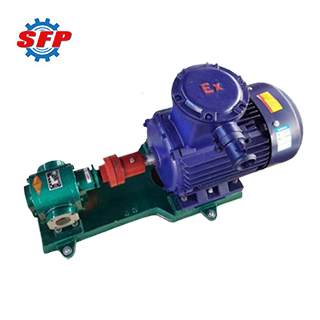

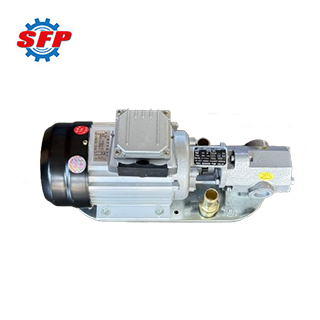

YHCB series arc circular gear pump adopts a special double arc sine curve tooth profile, so there's no relative sliding during operation, which means the volumetric efficiency can be over 60%. This pump is designed to move low-viscosity, non-corrosive, solid-particle-free oils and chemical liquids, and it is able to be used in lots of areas like car tuning, construction machinery, metallurgy and ceramics, mining and smelting, environmental protection, and firefighting.

Product Details:

YHCB series gear oil pump consists of two gears, a pump body, and front and rear covers. When the gears rotate, the teeth on the suction side gradually disengage, increasing the volume between the teeth and creating a vacuum area. Under this pressure, liquid is drawn into the pump body. As the gears continue to rotate, the drawn-in liquid is transported to the discharge side. On the discharge side, the gear teeth gradually mesh, and the space between the teeth gradually decreases, thereby compressing the liquid and forcing it out of the pump body.

Application:

YHCB series oil gear pumps are primarily suited for conveying non-corrosive liquids with viscosities ranging from 5 to 1500 cSt, temperatures not exceeding 80°C, and free of solid particles. Typically, these include fuels such as gasoline, kerosene, diesel, mechanical lubricating oils, diamine acetate esters, amine acetate esters, and methylamine acetate esters. Alternatively, different materials for components can be selected to achieve the purpose of conveying chemical media such as acids, alkalis, benzene, toluene, xylene, alcohols, olefins, esters, and ketones at appropriate concentrations.

Feature:

1. The gears of the pump can be made of steel, copper, nylon, or other materials to meet the needs of different medium transportation requirements.

2. It features smooth operation and low noise, with continuous meshing of the arc-shaped gears and a high overlap coefficient, ensuring that the overall noise level does not exceed 75 dB.

3.It adopts a double-arc wheel structure and applies advanced new technologies and processes in gear design, resulting in significantly improved performance compared to traditional gear pumps.

Performance Data:

| Model |

Capacity(m³/h) |

Pressure

(Mpa) |

Speed

(r/min) |

Efficiency

(%) |

Npshr

(m) |

| 50YHCB-15 |

15 |

0.6 |

960 |

70 |

5 |

| 50YHCB-20 |

20 |

0.2 |

1100 |

70 |

5 |

| 65YHCB-30B |

30 |

0.4 |

970 |

70 |

5 |

| 65YHCB-35 |

35 |

0.6 |

1440 |

70 |

5 |

| 65YHCB-35A |

35 |

0.6 |

960 |

70 |

5 |

| 76YHCB-40 |

40 |

0.6 |

1440 |

70 |

5 |

| 76YHCB-40A |

40 |

0.6 |

970 |

70 |

5 |

| 76YHCB-40B |

40 |

0.4 |

970 |

70 |

5 |

| 76YHCB-50 |

50 |

0.6 |

970 |

70 |

5 |

| 80YHCB-60 |

60 |

0.6 |

970 |

70 |

5 |

| 80YHCB-60A |

60 |

0.6 |

970 |

70 |

5 |

| 80YHCB-60B |

60 |

0.4 |

970 |

70 |

5 |

| 80YHCB-80 |

80 |

0.6 |

970 |

70 |

5 |

| 100YHCB-100 |

100 |

0.4 |

970 |

70 |

5 |

| 150YHCB-150 |

150 |

0.4 |

980 |

70 |

5 |

| 200YHCB-200 |

200 |

0.4 |

740 |

70 |

5 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)