Summarize:

.jpg)

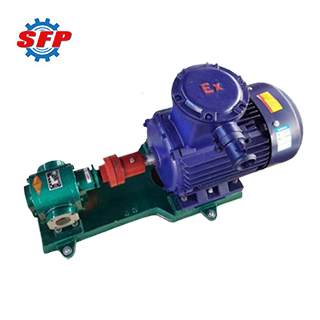

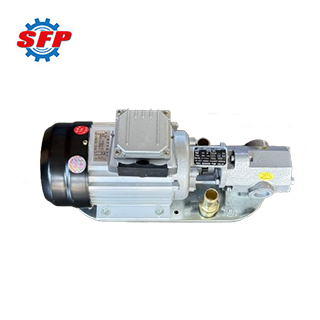

SHHLB series internal gear pump is a positive displacement pump specifically designed to handle liquid media of varying properties and viscosities in industries such as petroleum, chemical, coatings, food, and pharmaceuticals. This equipment features low-shear and pulsation-free operation, preserving the inherent characteristics of media like chocolate, vaccines, asphalt, resins, coatings, and paraffin wax during transfer to ensure their final quality. Additionally, its jacket insulation and high-temperature sealing design maintain stable medium temperatures up to approximately 200°C, enabling smooth and reliable transfer processes.

Product Details:

SHHLB internal gear pump primarily consists of an inner rotor, outer rotor, shaft, pump body, front cover, bracket, seals, bearings, and other components. The motor transmits power to the pump shaft via a coupling, driving the inner rotor to rotate, which in turn causes the outer rotor, meshing with the inner rotor's gear teeth to operate, forming variable-volume sealed chambers. As the suction-side chamber gradually expands, it creates negative pressure that rapidly draws high-viscosity media into the inlet, where the chamber continues rotating with the rotors toward the discharge side. Finally, the fluid is smoothly pushed toward the outlet under pulsation-free, low-shear compression.

Application:

1. Food: Chocolate, malt syrup, honey, jam, condensed milk, and similar media can be conveyed.

2. Chemicals: Capable of handling resins, adhesives, paints, inks, rubber solutions, and polymers.

3. Household: Laundry detergent, dishwashing liquid, body wash, soap pellets, fragrances, candles, and car wax.

4. High-viscosity oils: Capable of conveying heavy oil, fuel oil, asphalt, paraffin, crude oil, biodiesel, and silicone oil.

Feature:

1. It delivers stable high-pressure, pulsation-free output, offering a viable direct replacement for screw pumps in certain applications.

2. This equipment handles a wide range of materials, smoothly conveying everything from asphalt and resin to honey and chocolate.

3. Its front-opening design enables maintenance and cleaning without disassembling piping, significantly reducing downtime.

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)