Summarize:

.jpg)

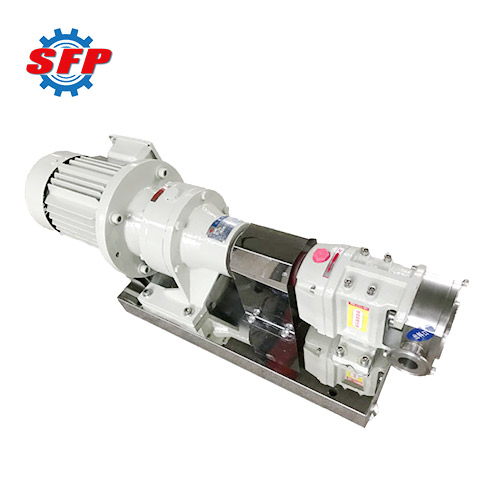

3RP rotary lobe pump is a positive displacement pump suitable for conveying suspensions, corrosive media, and emulsions with viscosities ranging from 30 cst to 100,000 cst and containing solid particles. In order to meet the stringent requirements of food, daily chemical, and biopharmaceutical production, all components in contact with the medium are constructed from sanitary-grade stainless steel to ensure the medium remains uncontaminated during conveyance.

Product Details:

3RP series rotary lobe pumps primarily utilize gear transmission to rotate the rotors for conveying media. Employing a gear-driven mechanism, the main shaft and auxiliary shaft drive the rotors to rotate synchronously in opposite directions. This causes volumetric changes within the pump chamber, generating higher vacuum levels and discharge pressures. These pumps are particularly suitable for sanitary-grade media as well as highly corrosive and high-viscosity substances. Additionally, the pump body incorporates a high-strength cast iron gearbox, helical gears, and heavy-duty bearings to ensure long-term stable operation.

.jpg)

Application:

1. Chemicals: Acrylic emulsion, PU resin, adhesives, asphalt unloading.

2. Food: Tomato sauce, chocolate paste, honey, dairy product filling lines.

3. Personal Care: Shampoo, face cream, laundry detergent, toothpaste base.

4. Pharmaceuticals: Syrups, ointments, vaccine bulk solutions, concentrated traditional Chinese medicine extracts.

5. Environmental Protection: Sludge feeding into plate-and-frame presses, oily wastewater, activated carbon slurry.

Feature:

1. This pump features outstanding self-priming capability, eliminating the need for additional priming operations. This significantly simplifies startup procedures and enhances operational efficiency.

2. It is designed with an advanced three-lobe screw rotor to achieve smooth, pulsation-free material conveyance, effectively reducing shear and compression forces to preserve the material's original properties.

4. It is equipped with double-ended mechanical seals or magnetic drive seals, it guarantees zero leakage when conveying toxic, hazardous, flammable, explosive, or valuable materials, safeguarding production safety and environmental hygiene.

3. The overflow components are crafted from 304 or 316L stainless steel and wear-resistant alloy steel. Special surface coatings can be applied to enhance wear and corrosion resistance, ensuring adaptability to various harsh operating conditions.

Performance Data:

|

Model

|

Flow

(L/100r)

|

Pressure

(bar)

|

Inlet/Outlet Size

(mm)

|

Rev

(r/min)

|

|

3RP-25

|

6

|

≤10

|

25

|

≤600

|

|

3RP-32

|

9

|

≤10

|

32

|

|

3RP-40

|

18

|

≤10

|

40

|

|

3RP-50

|

36

|

≤10

|

50

|

|

3RP-65

|

60

|

≤10

|

65

|

|

3RP-80

|

105

|

≤10

|

80

|

|

3RP-100A

|

125

|

≤10

|

100

|

|

3RP-100

|

150

|

≤10

|

100

|

| 3RP-125 |

250 |

≤10 |

125 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.jpg)