.jpg)

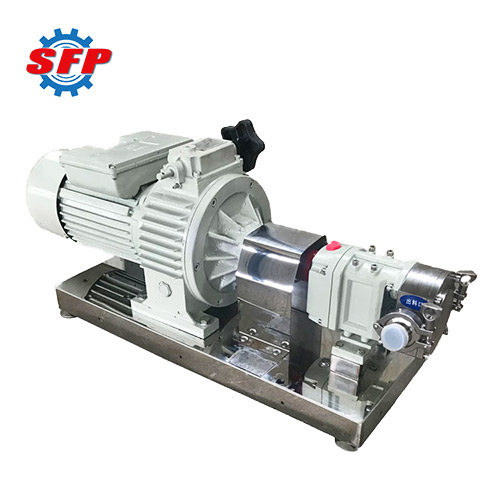

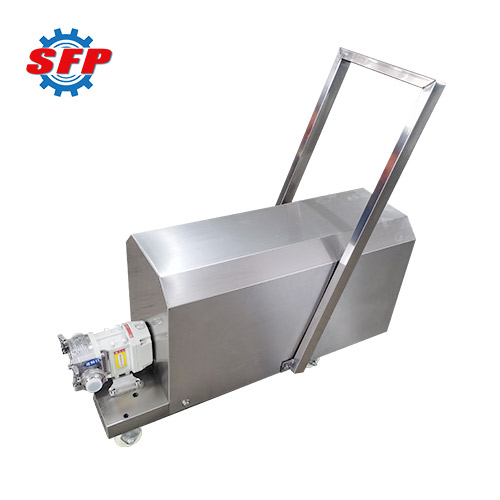

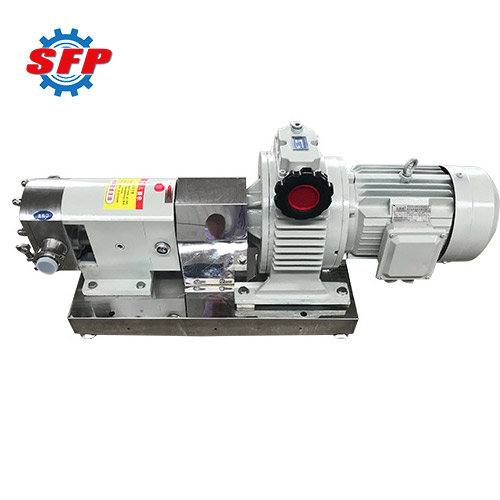

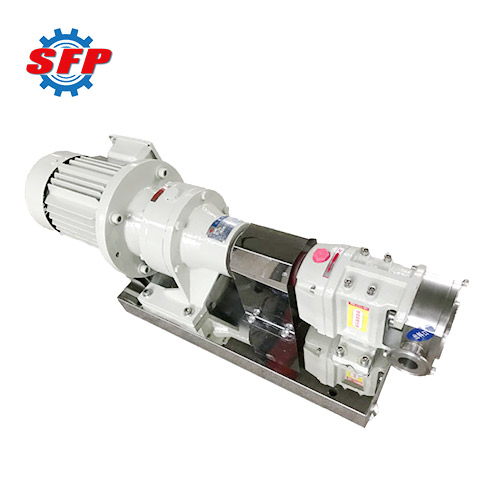

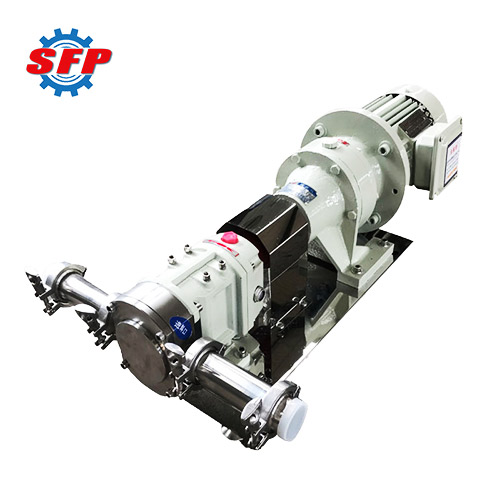

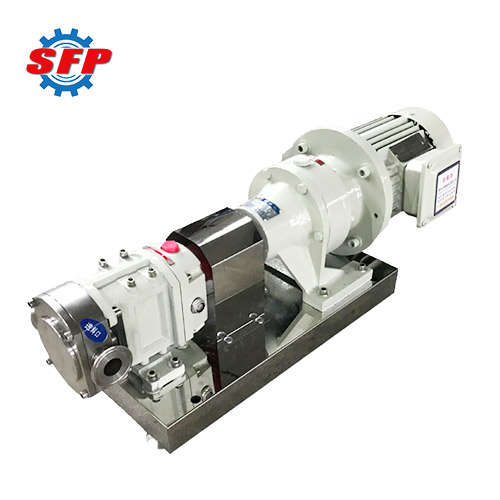

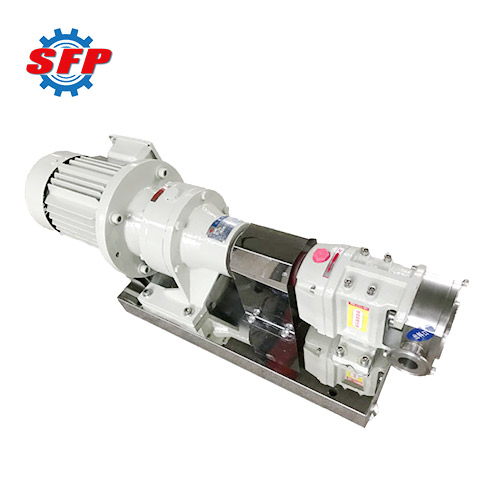

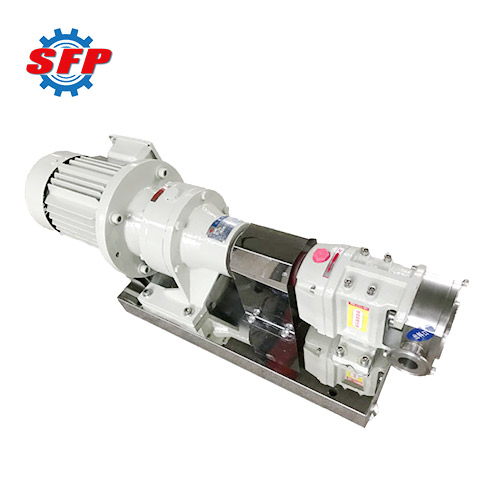

3RP rotary lobe pump is a multi-purpose two-way displacement pump with the advantages of self-priming capability, high efficiency, long service life and high accuracy. It is usually suitable for conveying and filling high viscosity liquids with corrosive and suspending properties, such as honey, sauces, skin creams, toothpastes and so on. As a result, it is widely used in the fields of food, beverage, chemical fiber, paper making, and biopharmaceuticals.

3RP series high viscosity lobe pump is mainly composed of rotor, shaft seal, gear box, a pair of synchronous meshing of the active gear, driving the rotor to transport media. Adopted is the gear transmission mode, the main shaft and auxiliary shaft drive the rotor synchronous reverse rotation, so that the pump volume changes, so as to form a high degree of vacuum and discharge pressure. This method is especially suitable for conveying sanitary fluids and corrosive high-viscosity fluids.

.png)

(2).png)

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/Outlet (mm) |

|

| L/100r | m³/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||