.jpg)

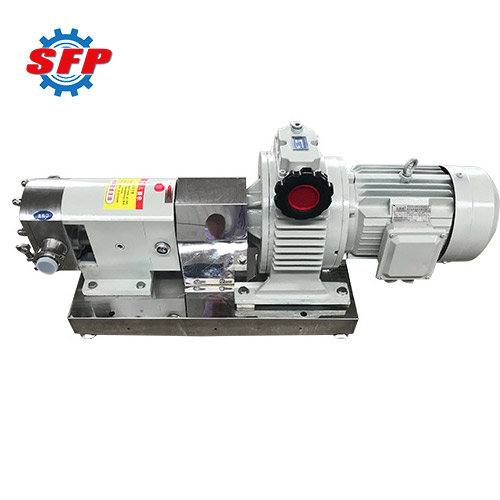

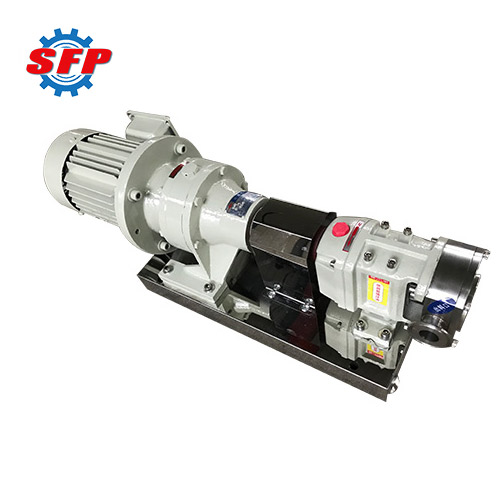

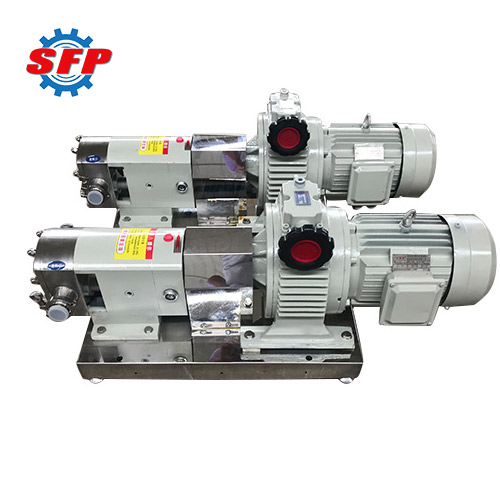

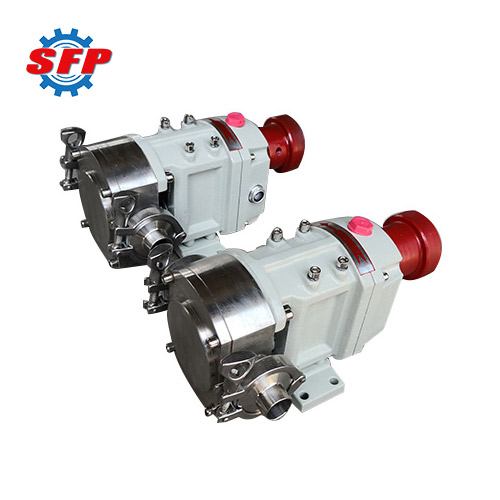

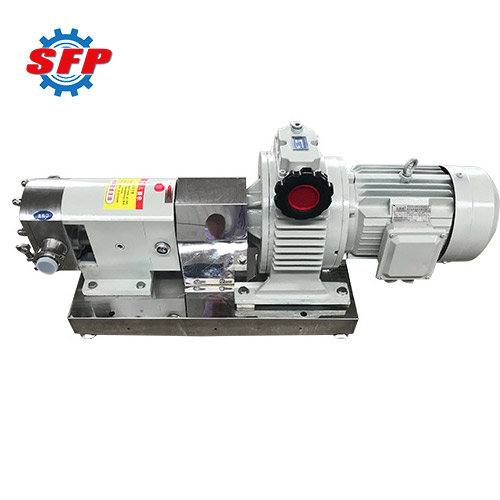

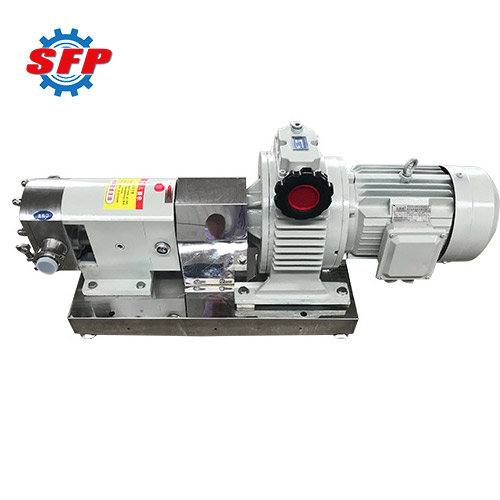

3RP series food grade lobe pump belongs to a kind of positive displacement pumps with stable flow, good self-priming performance, high efficiency and low energy consumption. In principle, the pump is not limited by the physical and chemical properties of the medium, so it can be used to deal with suspended liquids containing solid particles, corrosive and hygienic requirements of the medium. Therefore, it can be widely used in daily chemical, petroleum, biopharmaceutical, brewing, food and other processing industries.

(3).png)

(5).png)

(5).png)

|

Iteam |

Medium |

Viscosity Range(cp) |

Media Characteristics |

Select for lobe pump |

|

1 |

Chocolate (liquid) |

3,000-20,000 |

High viscosity with crystal, |

Mechanical seal , |

|

2 |

Syrup |

1,000-20,000 |

High viscosity, |

Lower speed, |

|

3 |

Maltose |

3,000-20,000 |

High viscosity, |

Lower speed, |

|

4 |

Molasses |

2,000-100,000 |

High viscosity, |

Lower speed, |

|

5 |

Honey |

2,000-10,000 |

High viscosity, |

Lower speed, |

|

6 |

Sucrose |

10-5,000 |

High viscosity with crystal, |

Lower speed, |

|

7 |

Beet Sugar |

100-8,000 |

High viscosity, |

Lower speed, |

|

8 |

For other liquids, please contact the sales staff |

|||

| Model | Flow | Discharge Pressure (Mpa) |

Rev (rpm) |

Motor Power (kw) |

Inlet/Outlet (mm) |

|

| l/100r | m³/h | |||||

| 3RP-25 | 6 | ≤1.8 | 0-1.0 | 10-400 | 0.75 | 25 |

| 3RP-32 | 9 | ≤2.7 | 1.1 | 32 | ||

| 3RP-40 | 18 | ≤4.3 | 1.5 | 40 | ||

| 3RP-50 | 36 | ≤8.6 | 2.2 | 50 | ||

| 3RP-65 | 60 | ≤14.4 | 4 | 65 | ||

| 3RP-80 | 105 | ≤25.2 | 11 | 80 | ||

| 3RP-100A | 125 | ≤30 | 15 | 100 | ||

| 3RP-100 | 150 | ≤36 | 18.5 | 100 | ||

| 3RP-125 | 250 | ≤60 | 22 | 125 | ||