Summarize:

.jpg)

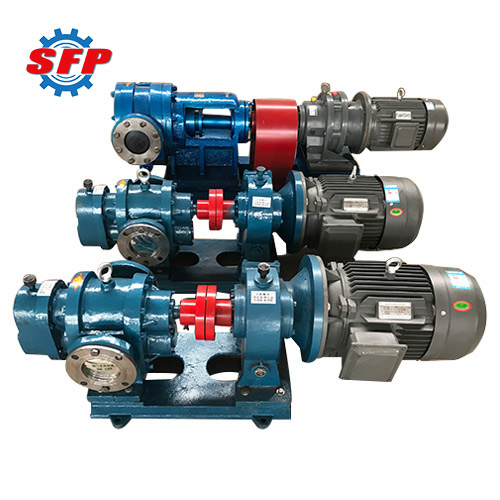

LC series high viscosity oil pump is a positive displacement pump characterized by low speed, high efficiency, compact size, high flow rate, low power consumption, strong self-priming capability, no need for priming oil, and ease of use. This series of pumps is available in two drive configurations: belt-driven and gear reducer-driven. They can be widely applied in industries such as chemicals, construction, papermaking, biotechnology, petroleum, and pharmaceuticals, handling media such as toothpaste, crude oil, paint, lubricating oil, syrup, and yeast.

Product Details:

LC series roots gear pump is mainly composed of pump body, rotor, parallel shaft, synchronous gears, bearings and seals. Two rotors are mounted perpendicular to each other on a pair of parallel shafts, and synchronized rotary motion is reversed by a pair of gears. There is a certain clearance between the rotors and the inner wall of the pump casing to realize high speed operation.

Application:

LC series high viscosity oil pump can be widely employed in the transportation of petroleum and petroleum products as well as in factories to transport a wide range of oils and liquids, including crude oil, paints, lubricants, vitreous enamel, oleic acid, toothpaste and light alkaline liquids. In food processing, it conveys a variety of liquids such as soy sauce, gelatin and syrups. In addition, this machine can also be used for loading and unloading a variety of tankers, which are fast, efficient, easy to use and reversible.

Feature:

1. With strong self-priming ability, it can quickly self-priming and put into work without drawing oil.

2. In the case of small volume, it can realize large flow rate output and consume relatively small power.

3. It is characterized by low rotation and high efficiency, it can realize high efficiency liquid conveying under low rotation speed.

4. This machine can be widely employed for handling petroleum and petroleum products, various oils and liquids, such as crude oil, paint, lubricating oil, glass glue, grease acid, toothpaste and light alkaline liquids, etc.

Performance Data:

| Model |

Flow

m³/h |

Pressure

Mpa |

Inlet&Outlet Size

mm |

Motor |

Speed

r/min |

| Model |

Power

KW |

| LC-10/0.6 |

10 |

0.6 |

40 |

100L 2 -4 |

3.0 |

400 |

| LC-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112S-4 |

4.0 |

| LC-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LC-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LC-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

209 |

| LC-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

254 |

| LCT-10/0.6 |

10 |

0.6 |

40 |

100L 2 -4 |

3.0 |

400 |

| LCT-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112M-4 |

4.0 |

| LCT-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LCT-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LCT-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

209 |

| LCT-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

254 |

| LCW-10/0.6 |

10 |

10 |

40 |

100L 2 -4 |

3.0 |

400 |

| LCW-18/0.6 |

18 |

0.6 |

50 |

I 132S-4 |

5.5 |

400 |

| II 112M-4 |

4.0 |

| LCW-38/0.6 |

38 |

0.6 |

65 |

132M-4 |

7.5 |

400 |

| LCW-50/0.6 |

50 |

0.6 |

80 |

180M-4 |

11 |

445 |

| LCW-80/0.6 |

80 |

0.6 |

200 |

225M-6 |

30 |

206 |

| LCW-100/0.6 |

100 |

0.6 |

200 |

250M-6 |

37 |

|

.jpg)

.jpg)