.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

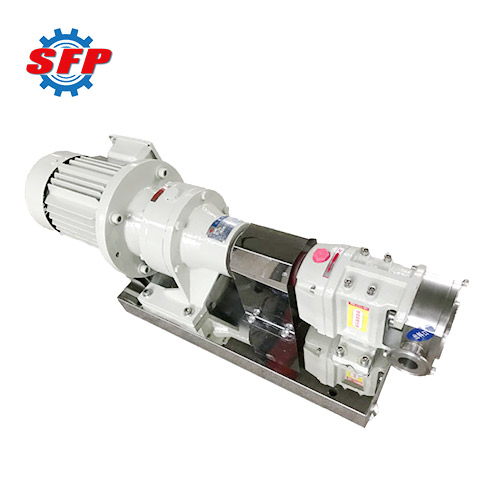

3RP rotary lobe pump is a typical rotary positive displacement pump suitable for conveying suspensions containing soft solid particles, corrosive media, and sanitary-grade fluids. This equipment handles media temperatures ranging from -30°C to 180°C and viscosities from 30 cst to 100,000 cst, meeting the conveying requirements of industries such as daily chemical, building materials, pharmaceuticals, petroleum, and food and beverage processing. To meet stringent production hygiene standards, it is constructed from food-grade stainless steel to minimize contamination and loss of the medium during filling operations.

.jpg)

.jpg)

|

Model |

Flow |

Pressure |

Rev |

Power |

Inlet/Outlet Size |

|

|

(L/100r) |

(m³/h) |

(Mpa) |

(rpm) |

(kW) |

(mm) |

|

|

3RP-25 |

6 |

≤1.8 |

0-1.0 |

≤600 |

0.75 |

25 |

|

3RP-32 |

9 |

≤2.7 |

0-1.0 |

1.1 |

32 |

|

|

3RP-40 |

18 |

≤4.3 |

0.-1.0 |

1.5 |

40 |

|

|

3RP-50 |

36 |

≤8.6 |

0-1.0 |

2.2 |

50 |

|

|

3RP-65 |

60 |

≤14.4 |

0-1.0 |

4 |

65 |

|

|

3RP-80 |

105 |

≤25.2 |

0-1.0 |

11 |

80 |

|

|

3RP-100A |

125 |

≤30 |

0-1.0 |

15 |

100 |

|

|

3RP-100 |

150 |

≤36 |

0-1.0 |

18.5 |

100 |

|

|

3RP-125 |

250 |

≤60 |

0-1.0 |

22 |

125 |

|