Summarize:

.jpg)

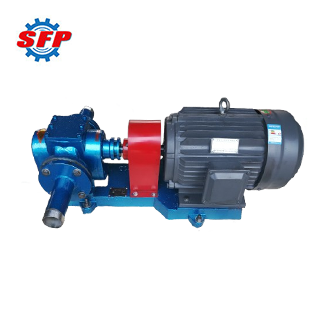

KCB series oil gear pumps are specifically designed for conveying non-corrosive lubricating liquids with viscosities ranging from 5 to 1500 centistokes (cst). With their simple and reliable construction, stable output characteristics, and excellent adaptability to high-viscosity media, these pumps have become a dependable choice for conveying lubricating oils, fuel oils, asphalt, paints, greases, resins, and various chemical raw materials. Whether in hydraulic systems, lubrication systems, or asphalt insulation conveyance, this equipment consistently delivers smooth, precise, and efficient flow power over extended periods, making it an indispensable component in production processes.

Product Details:

KCB series lubricating oil gear pump primarily consists of gears, shafts, pump bodies, valves, and shaft end seals. During operation, when the motor drives the drive gear to rotate, it causes the driven gear to rotate in the opposite direction. On the suction side, the gears disengage, increasing the volume between the teeth to create a vacuum, thereby drawing in the medium. As the gears rotate, the medium is transported to the discharge side, where the gears re-engage, reducing the volume between them. This forces the medium out, achieving stable and continuous positive displacement pumping.

Application:

1. Fuel Systems: Loading and unloading, transfer, and boiler fuel supply for diesel, heavy oil, and residual oil.

2. Asphalt & Road Construction: Asphalt tank farm circulation, asphalt mixing plant feeding, asphalt sprayers.

3. Chemical Processes: Metering and conveying of resins, pigments, paints, inks, adhesives, and similar materials.

4. Lubricant Industry: Oil depot loading/unloading, drum filling, lubricant blending systems, centralized oil supply systems.

5. Hydraulic Systems: Serving as hydraulic oil source pumps to provide stable pressure oil for small to medium-sized hydraulic stations.

Feature:

1. The pump features exceptional self-priming capability, enabling self-priming without external assistance for simplified operation, making it particularly suitable for specialized and demanding work environments.

2. It employs a gear-meshing structure with integrated vibration damping design, ensuring a quiet working environment during operation and delivering low-noise performance.

3. The pump body is constructed from premium materials to ensure long-term stable operation and reduce failure rates.

Performance Data:

| Model |

Capacity Q |

Speed |

Exhaust pressure P |

Motor |

| m³/h |

l/min |

r/min |

Mpa |

Power Kw |

| KCB-18.3 |

1.1 |

18.3 |

1400 |

1.45 |

1.5 |

| KCB-33.3 |

2 |

33.3 |

1420 |

1.45 |

2.2 |

| KCB-55 |

3.3 |

55 |

1400 |

0.33 |

1.5 |

| KCB-83.3 |

5 |

83.3 |

1420 |

0.33 |

2.2 |

| KCB-135 |

8 |

135 |

940 |

0.33 |

2.2 |

| KCB-200 |

12 |

200 |

1440 |

0.33 |

4 |

| KCB-300 |

18 |

300 |

960 |

0.36 |

5.5 |

| KCB-483.3 |

29 |

483.3 |

1440 |

0.36 |

7.5 |

| KCB-633 |

38 |

633 |

970 |

0.28 |

11 |

| KCB-960 |

58 |

960 |

1470 |

0.28 |

11 |

| KCB-1200 |

72 |

1200 |

740 |

0.6 |

37 |

| KCB-1600 |

96 |

1600 |

980 |

45 |

| KCB-1800 |

110 |

1800 |

740 |

0.6 |

55 |

| KCB-2500 |

150 |

2500 |

985 |

75 |

| KCB-2850 |

170 |

2850 |

740 |

0.6 |

90 |

| KCB-3800 |

230 |

3800 |

989 |

110 |

| KCB-4100 |

245 |

4100 |

743 |

0.6 |

132 |

| KCB-5400 |

325 |

5400 |

989 |

160 |

| KCB-5600 |

330 |

5600 |

744 |

0.6 |

160 |

| KCB-7600 |

460 |

7600 |

989 |

200 |

| KCB-7000 |

420 |

7000 |

744 |

0.6 |

185 |

| KCB-9600 |

570 |

9600 |

989 |

250 |

| KCB-13000 |

800 |

13000 |

490 |

0.6 |

315 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)