Summarize:

.jpg)

KCB series gear pump is a classic external spur gear pump designed for conveying non-corrosive lubricants such as crude oil, diesel, lubricating oil, vegetable and animal oils, as well as liquids free of solid particles and fibers. To ensure long-term stable operation under harsh conditions, the pump features advanced gear design and wear-resistant materials, delivering reliable and efficient pumping performance for industries including chemical, petroleum, metallurgy, power generation, and mining.

Product Details:

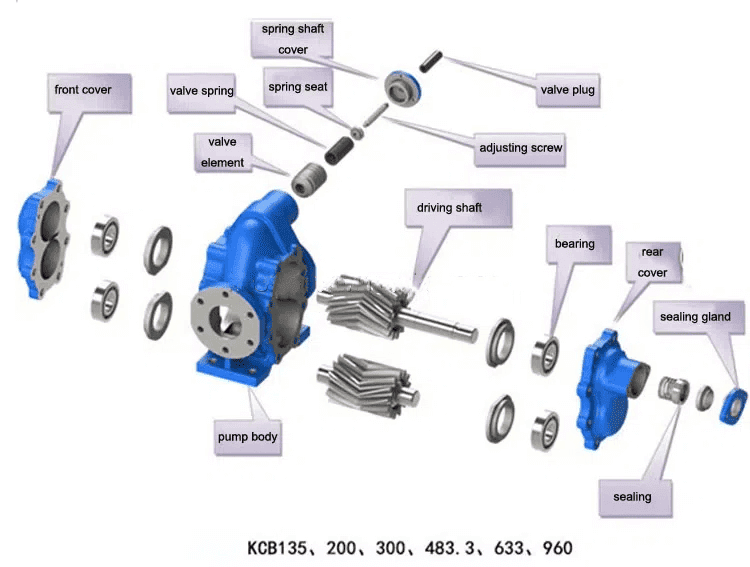

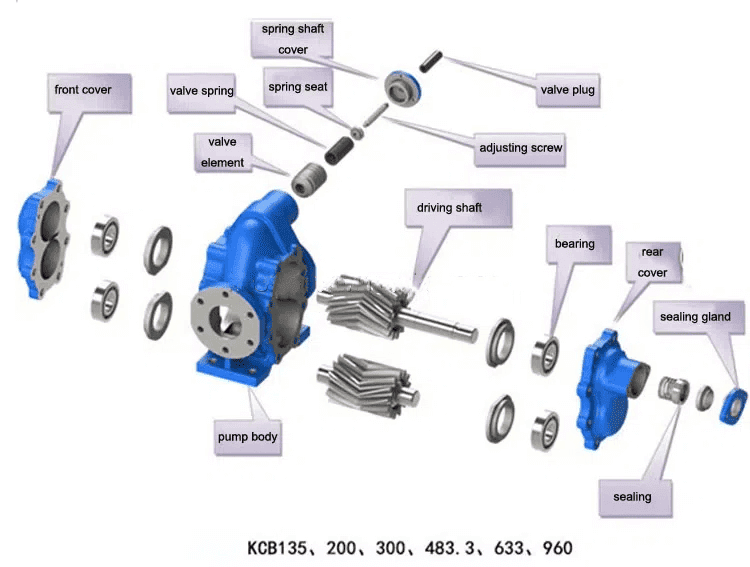

KCB series lubricating oil gear pump primarily consists of gears, shafts, pump bodies, valves, and shaft end seals. During operation, internal components are automatically lubricated by the output medium. Additionally, to minimize the torque exerted on the gears during operation, the KCB series gear pump employs a rational configuration of oil discharge and return tanks.

Application:

1. Pulp and Paper Industry: Acids, soap solutions, alkali solutions, black liquor, kaolin, lime, latex, sludge.

2. etrochemical Industry: Pure asphalt or filler asphalt, tar, diesel, crude oil, lubricating oil.

3. Food Industry: Chocolate, cocoa butter, fillers, sugars, vegetable oils, molasses.

4. Chemical Industry: Sodium silicate, acids, plastics, mixed chemicals.

Feature:

1. Featuring exceptional self-priming capability, it achieves self-priming without external assistance, offering simple operation and making it particularly suitable for specific demanding work environments.

2. To ensure a quiet working environment during operation, we have optimized the gear meshing structure and incorporated vibration-damping design, guaranteeing low-noise performance.

3. The pump body utilizes premium materials for both gears and casing, ensuring long-term stable performance and reducing the probability of failure.

Performance Data:

| Model |

Capacity Q |

Speed |

Exhaust pressure P |

Motor Power |

| m³/h |

l/min |

r/min |

Mpa |

Kw |

| KCB-18.3 |

1.1 |

18.3 |

1400 |

1.45 |

1.5 |

| KCB-33.3 |

2 |

33.3 |

1420 |

1.45 |

2.2 |

| KCB-55 |

3.3 |

55 |

1400 |

0.33 |

1.5 |

| KCB-83.3 |

5 |

83.3 |

1420 |

0.33 |

2.2 |

| KCB-135 |

8 |

135 |

940 |

0.33 |

2.2 |

| KCB-200 |

12 |

200 |

1440 |

0.33 |

4 |

| KCB-300 |

18 |

300 |

960 |

0.36 |

5.5 |

| KCB-483.3 |

29 |

483.3 |

1440 |

0.36 |

7.5 |

| KCB-633 |

38 |

633 |

970 |

0.28 |

11 |

| KCB-960 |

58 |

960 |

1470 |

0.28 |

11 |

| KCB-1200 |

72 |

1200 |

740 |

0.6 |

37 |

| KCB-1600 |

96 |

1600 |

980 |

45 |

| KCB-1800 |

110 |

1800 |

740 |

0.6 |

55 |

| KCB-2500 |

150 |

2500 |

985 |

75 |

| KCB-2850 |

170 |

2850 |

740 |

0.6 |

90 |

| KCB-3800 |

230 |

3800 |

989 |

110 |

| KCB-4100 |

245 |

4100 |

743 |

0.6 |

132 |

| KCB-5400 |

325 |

5400 |

989 |

160 |

| KCB-5600 |

330 |

5600 |

744 |

0.6 |

160 |

| KCB-7600 |

460 |

7600 |

989 |

200 |

| KCB-7000 |

420 |

7000 |

744 |

0.6 |

185 |

| KCB-9600 |

570 |

9600 |

989 |

250 |

| KCB-13000 |

800 |

13000 |

490 |

0.6 |

315 |

.png)

.png)

.jpg)

.jpg)