Summarize:

.jpg)

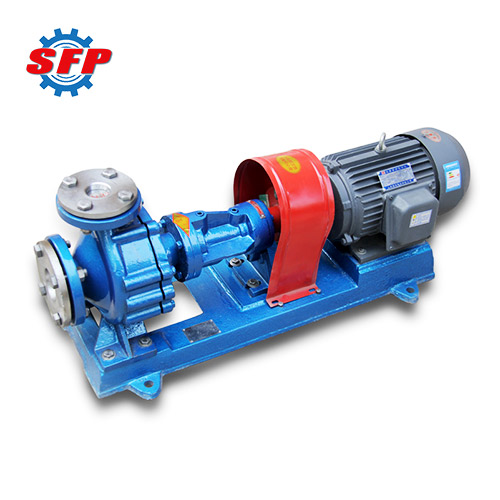

IHG series vertical centrifugal chemical pump is the latest generation of vertical centrifugal pumps manufactured in accordance with international standards, using the most advanced hydraulic model, with the characteristics of high efficiency and energy saving, small footprint, low investment in construction, low noise, no pollution, etc. It is the ideal equipment for urban water supply, high-rise buildings and long-distance water supply, and conveying clear water and other liquids with physical and chemical properties similar to clear water.

Product Details:

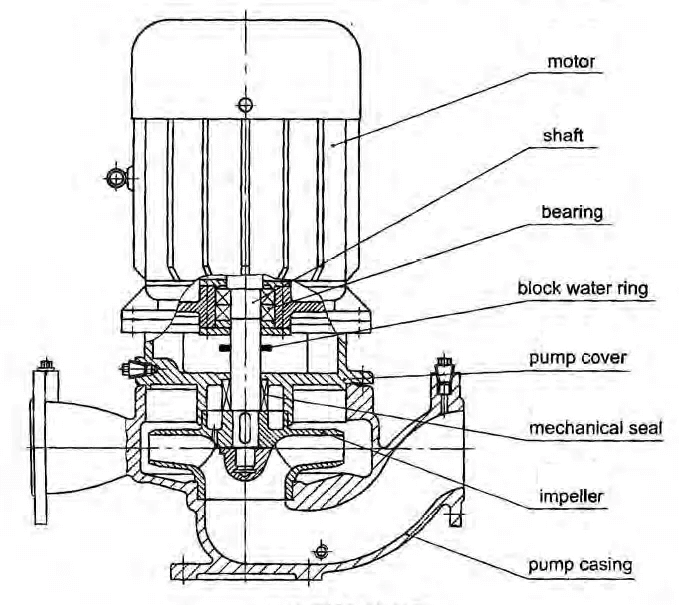

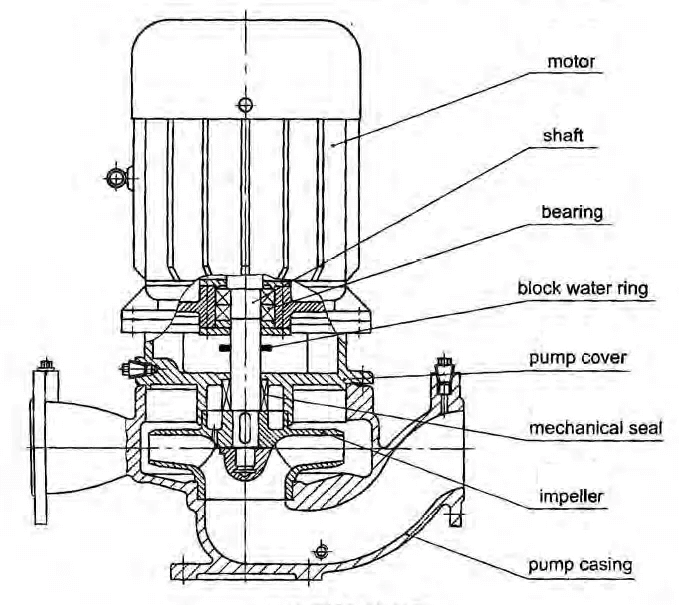

IHG series vertical shaft centrifugal pumps are composed of electronics, pump body, bearing sealing ring and other components. When the pump works, the motor will drive the pump shaft and impeller to rotate, and the liquid will be thrown out to the outer edge under the action of centrifugal force. At the same time, a certain vacuum will be formed at the center of the impeller, and the pressure at the inlet liquid surface is higher than that at the center of the impeller, so the liquid will enter the pump under the action of differential pressure. Therefore, the impeller keeps rotating, and the liquid is continuously sucked in and pressed out.

Application:

1. It is suitable for industrial and urban water supply and drainage, high-rise building pressurized water supply, garden sprinkler irrigation, fire pressurization, long-distance transportation, HVAC refrigeration cycle, bathroom and other cold and warm water circulation pressurization and equipment matching.

2. This machine is able to used in metallurgy, chemical industry, textile, wood processing, papermaking, and high-temperature hot water pressurized circulation transportation of boilers in restaurants, bathrooms, hotels, etc., as well as pumps for urban housing heating circulation.

3. It can be used in petroleum, chemical, metallurgy, electric power, papermaking, food, pharmaceutical and synthetic fiber departments, and the operating temperature is -20°C ~ 120°C.

Feature:

1. Its impeller is directly installed on the elongated shaft of the motor, with short axial dimension and compact structure. The pump and motor bearings are reasonably arranged, which can effectively balance the radial and axial loads generated by the operation of the pump, thereby ensuring the smooth operation of the pump.

2. This pump is a vertical structure, with the same inlet and outlet diameters and located on the same center line. It can be installed in the pipeline like a valve. It has a compact and beautiful appearance, small footprint and low construction investment. The protective cover can be used outdoors.

3. The shaft seal adopts mechanical seal or mechanical seal combination, adopts imported titanium alloy sealing ring, medium-sized high temperature resistant mechanical seal and hard alloy material, wear-resistant seal, which can effectively increase the service life of mechanical seal.

4. It can adopt the series and parallel operation modes of the pump according to the requirements of use, that is, the needs of flow and head.

Performance Data:

| Model |

Capacity

(m³/h) |

Lift Head

(m) |

Speed

(r/min) |

Motor

(KW) |

Inlet&Outlet Diameter

(mm) |

| 15-80 |

1.1

1.5

2.0 |

8.5

8

7 |

2800 |

0.18 |

15 |

| 20-110 |

1.8

2.5

3.3 |

16

15

13.5 |

2800 |

0.37 |

20 |

| 20-160 |

1.8

2.5

3.3 |

33

32

30 |

2900 |

0.75 |

20 |

| 25-110 |

2.8

4

5.2 |

16

15

13.5 |

2900 |

0.55 |

25 |

| 25-125 |

2.8

4

5.2 |

20.6

20

18 |

2900 |

0.75 |

25 |

| 25-125A |

2.5

3.6

4.6 |

17

16

14.4 |

2900 |

0.55 |

25 |

| 25-160 |

2.8

4

5.2 |

33

32

30 |

2900 |

1.5 |

25 |

| 25-160A |

2.6

3.7

4.9 |

29

28

26 |

2900 |

1.1 |

25 |

| 32-100 |

4.5 |

12.5 |

2900 |

0.55 |

32 |

| 32-100(I) |

4.4

6.3

8.3 |

13.2

12.5

11.3 |

2900 |

0.75 |

32 |

| 32-125 |

3.5

5

6.5 |

22

20

18 |

2900 |

0.75 |

32 |

| 32-125A |

3.1

4.5

5.8 |

17.6

16

14.4 |

2900 |

0.55 |

32 |

| 32-160 |

6.5 |

32 |

2900 |

1.5 |

32 |

| 32-160A |

4 |

25 |

2900 |

1.1 |

32 |

| 32-160(I) |

4.4

6.3

8.3 |

33.2

32

30.2 |

2900 |

2.2 |

32 |

.jpg)