Summarize:

.jpg)

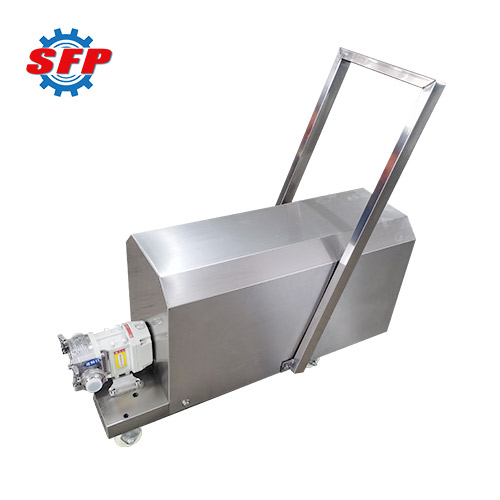

3RP series sanitary lobe pumps are specifically designed for handling solid particle suspensions and corrosive liquid media. They feature strong self-priming capability, high corrosion resistance, superior hygiene standards, and extended service life. With low shear and pulsation-free operation, these pumps reliably convey products like meat paste, jam, and chemical substances while preserving the original properties of the media and ensuring consistent texture. Hence, they are widely used in processing industries such as food, beverage, cosmetics, pharmaceuticals, petroleum, and chemicals.

Application:

1. In construction, it handles ceramic glazes, interior/exterior wall coatings, and waterproofing materials.

2. This pump meets industrial requirements for conveying resins, paints, dyes, latex, lubricants, and emulsified asphalt.

3. In the food industry, it can be used to convey media such as yogurt, cream, jam, syrup, beer, yeast, condiments, and edible oils.

4. The pharmaceutical industry can smoothly transport various substances, including syrups, vaccines, nutritional solutions, royal jelly, and biological products.

5. In the daily chemical industry, it is commonly used to convey raw materials such as facial cleansers, toothpaste, perfumes, detergents, cosmetics, and glycerin.

Feature:

1. Its rotor features a zero-friction coefficient clearance design, significantly extending pump service life.

2. Integrated variable frequency drives enable flexible flow rate adjustment, transforming it into a versatile metering pump.

3. This equipment delivers superior pumping performance whether conveying high-viscosity media or handling materials like gas-liquid-solid three-phase mixtures.

4. Its inlet and outlet ports can be customized with flange or threaded connections based on specific application requirements, and these ports can be connected via flanges or threads according to particular needs.

.png)

.png)

.jpg)

.png)

.jpg)