Summarize:

.jpg)

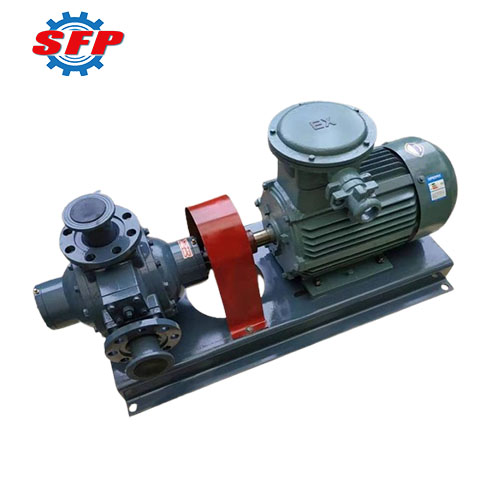

Lpg gas transfer pump is able to pump liquefied petroleum gas, liquid ammonia, propylene, propane, ethylene oxide, methanol and various volatile liquids or petroleum products with similar properties. This machine can be widely adopted in the fields of petroleum, chemical industry, liquefied gas plant, etc., especially suitable for charging workshop, cylinder filling, LPG backflow, liquefied gas storage, automobile fuel filling and other places. At the same time, the pump is equipped with complete safety protection devices, such as overload protection and leakage protection to ensure safety and reliability during operation.

Product Details:

LPG gas pump is a positive displacement vane pump with advanced structure. The stator surface is made of composite curved surface, mechanical seals are used at both ends, and "O" type sealing rings are used on each fixed end face. When the rotor rotates, the volume of the oil inlet chamber gradually increases, forming negative pressure and generating suction, thereby sucking in the oil. When the rotor rotates to a certain angle, the volume gradually decreases, thereby discharging the oil. In addition, the matching parts of the rotating motion are all metal rather than non-metal, which is safe and reliable to use and has the function of one machine with multiple uses.

Application:

1. It can be filled from cylinder to cylinder using a filling gun and hose.

2. This machine can be used to transfer LPG pump, usually work with pipeline connection.

3. It is suitable for LPG car refueling station, cylinder filling of LPG for large and medium-sized users, loading and unloading of LPG tanker trucks, back-filling of LPG and other media transportation.

Feature:

1. This pump incorporates advanced technology and design, featuring high efficiency and energy savings to effectively reduce power consumption and operating costs.

2. It is equipped with comprehensive safety features, such as overload protection and leakage protection, ensuring safe and reliable operation.

3. The machine offers simple and convenient operation—simply follow the instructions to complete tasks without requiring specialized skills.

Performance Data:

| Model |

Speed

(r.p.m) |

Flow

(m³/h) |

Pressure Difference

(MPa) |

Working Pressure

(MPa) |

Power

(kW) |

Inlet Size

(inch) |

Outlet Size

(inch) |

Temperature Range

(℃) |

| YQB2-5 |

600 |

2 |

0.5 |

1.6 |

1.5 |

1 |

1 |

+40

-40 |

| YQB5-5 |

780 |

5 |

2.2 |

1.2 |

1.2 |

| YQB10-5 |

600 |

10 |

0.5 |

1.6 |

5.5 |

2 |

2 |

+40

-40 |

| YQB15-5 |

780 |

15 |

| YQB15-5A |

780 |

15 |

0.4 |

1.6 |

4 |

2 |

2 |

+40

-40 |

| YQB10-5A |

600 |

10 |

| YQB25-5 |

600 |

25 |

0.5 |

1.6 |

11 |

3 |

3 |

+40

-40 |

| YQB35-5 |

780 |

35 |

| YQB50-5 |

600 |

50 |

0.5 |

1.6 |

15 |

4 |

4 |

+40

-40 |

| YQB60-5 |

780 |

60 |

0.5 |

1.6 |

15 |

4 |

4 |

+40

-40 |

| YQB80-5 |

780 |

80 |

0.5 |

1.6 |

18.5 |

4 |

4 |

+40

-40 |

.jpg)

.jpg)

.jpg)