Summarize:

.jpg)

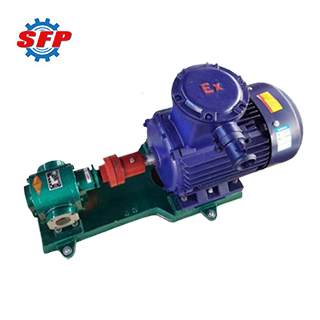

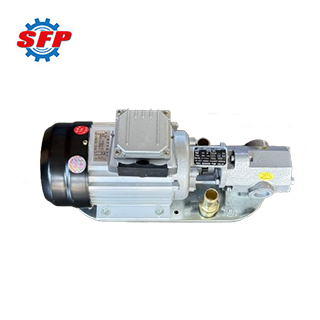

ZYB series gear oil transfer pumps are specially designed to handle media with temperature not higher than 260 °C, viscosity not greater than 150 mm²/s and containing non-metallic impurities, such as diesel oil, heavy oil, coal tar, motor oil and other media. As the pump has sealing and lubrication design and automatic adjustment structure, and the parts are made of high wear-resistant materials, it has the features of compact structure, strong anti-wear ability, strong applicability, high efficiency, etc., so it is especially suitable for occasions that require stable working pressure and long-term continuous conveying.

Product Details:

ZYB series gear pump is mainly composed of pump body, pump cover, gears, shaft seal, gland and other components. There are two active gears and passive gears of the same size installed in the pump body, and the outer diameter edge of the gears closely matches with the pump casing to form a sealed working chamber. When the motor drives its active gear to rotate, the passive gear also rotates. As the gears mesh, the volume between the teeth gradually decreases, and the oil is extruded and discharged from the discharge port.

.png)

.png)

Application:

ZYB series heavy oil gear pumps are capable of conveying heavy oil, diesel oil, coal tar and impurities containing non-metallic impurities with temperature not higher than 260 °C and viscosity not greater than 150 mm²/S. It can be used in food, petroleum, chemical, building materials and daily-use chemical industries, as well as strong lubrication system in fuel combustion system, fuel conveying and injection system. However, it should be noted that it is not suitable for conveying corrosive impurities, metal-containing impurities, sand and gravel impurities with a particle size larger than 3 mm and highly volatile impurities.

Feature:

1. The internal parts of the pump have been optimized design, the gears bear small torque in the work, the bearing load is small, the wear is small, so as to improve the efficiency of the pump.

2. The machine adopts self-sealing lubrication and gap automatic adjustment structure, reasonable design, shape and installation dimensions are the same as KCB series gear pumps, with interchangeability.

3. Due to its durable material and reasonable design structure, it is especially suitable for the occasions requiring stable working pressure and long-term continuous work, such as strong lubrication system, fuel delivery and injection in fuel combustion system.

Performance Data:

| Type |

Inlet & Outlet |

Flow |

Pressure |

Speed |

Suction Height |

Power |

| mm |

m³/h |

L/min |

MPa |

r/min |

m |

kw |

| ZYB4/0.6 |

25 |

4 |

66 |

0.6 |

960 |

5 |

1.5 |

| ZYB7/0.6 |

40 |

7 |

116 |

0.6 |

960 |

5 |

3 |

| ZYB13/0.6 |

50 |

13 |

216 |

0.6 |

960 |

5 |

4 |

| ZYB13/1.0 |

50 |

13 |

216 |

1.0 |

960 |

5 |

5.5 |

| ZYB18/0.6 |

70 |

18 |

300 |

0.6 |

960 |

5 |

7.5 |

| ZYB18/1.0 |

70 |

18 |

300 |

1.0 |

960 |

5 |

11 |

| ZYB30/0.6 |

80 |

30 |

500 |

0.6 |

960 |

5 |

7.5 |

| ZYB38/0.4 |

100 |

38 |

633 |

0.4 |

960 |

5 |

15 |

| ZYB45/0.6 |

100 |

45 |

750 |

0.4 |

960 |

5 |

18.5 |

| ZYB60/0.6 |

100 |

60 |

1000 |

0.4 |

960 |

5 |

22 |

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)