Summarize:

.jpg)

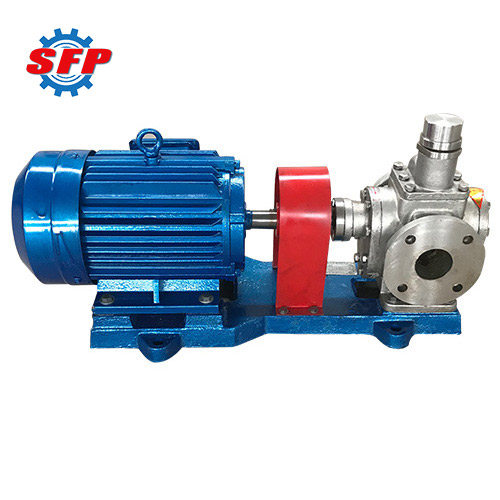

LB series gear pump for freezer is available for conveying all kinds of mechanical oils, turbine oils and other media with similar properties and smooth performance with viscosity below 200°E (1500mpa.s), no solid particles impurities and temperature not higher than 120°. The structure of the equipment is well-designed, not easy to be blocked, and the use of the equipment can improve the working efficiency.

Product Details:

LB series refrigerator oil gear pump installed in a variety of piping systems, used to provide media flow, head and flow direction. The outstanding feature of this pump is that there is no relative sliding of the tooth gallery surface in the process of gear combination, so there is no wear and tear of the tooth surface, balanced operation, no trapped liquid phenomenon, low noise, long life, high efficiency. This machine freed from the constraints of the traditional design, making the gear pump in the design, production of the use of long into a new category.

Application:

LB series gear oil pump is a major energy consumer, the annual pump power consumption accounts for about 20% of China's power generation, so the pump in the various production systems in the safety, reliability and economy is very important.

1. Application in steelmaking, mining, coal mining production system

2. In ships, vehicles, aircraft, rockets and a variety of sports machinery system;

3. In petrochemical, natural gas, crude oil product pipeline delivery system.

4. In fine chemical, pharmaceutical and food production system.

Feature:

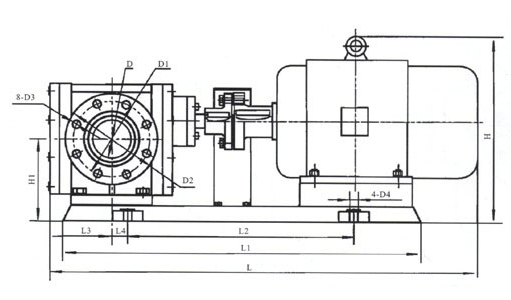

1. There are two forms of shaft end sealing: mechanical sealing and packing sealing, which can be selected according to the specific use and user requirements.

2. The product adopts double arc sine curve tooth shape, compared with involute gears, it has the advantages of no wear on the tooth surface, no liquid trapping phenomenon, long service life and so on.

3. There is a differential pressure safety valve as overload protection, the full return pressure of the safety valve is 1.5 times of the rated discharge pressure of the pump, and it can also be adjusted separately according to the actual needs within the range of allowable discharge pressure.

Performance Data:

| Model Number |

Suction and Discharge End Calibre (mm) |

Flow Rate m3/h |

Dropout Pressure MPa |

Discharge Pressure

pMpa |

| LB1.8 |

20 |

1.8 |

0.5 |

2.5 |

| LB3.6 |

25 |

3.6 |

0.5 |

2.5 |

| LB10 |

40 |

10 |

0.5 |

2.5 |

| LB12 |

40 |

12 |

0.5 |

2.5 |

| LB20 |

80 |

20 |

0.5 |

2.5 |

| LB25 |

80 |

25 |

0.5 |

2.5 |

| LB40 |

100 |

40 |

0.5 |

2.5 |

.jpg)

.jpg)