Summarize:

.jpg)

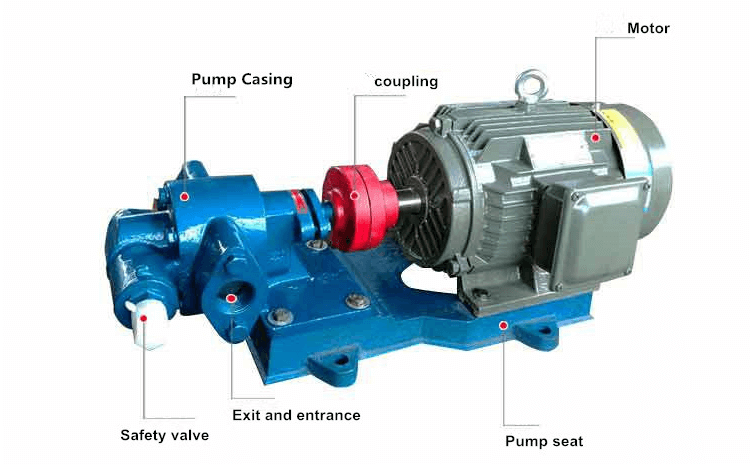

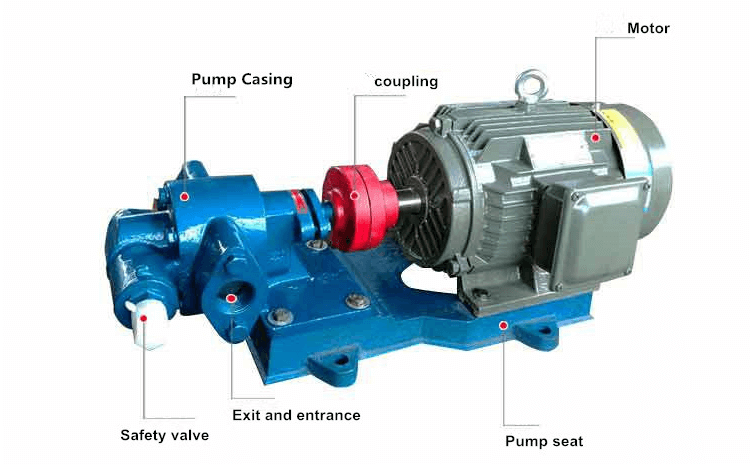

2CY series gear pump is an external gear pump characterized by high hardness, high wear resistance, high delivery efficiency, and stable operation. This pump is suitable for conveying non-corrosive lubricating oil media with temperatures below 300°C that contain no solid particles or fibers. It finds extensive application in mechanical lubrication systems, oil transfer systems, hydraulic transmission systems, boiler systems, and other industrial fields such as ships, oil depots, and mines.

Product Details:

2CY series horizontal gear pump primarily consists of gears, shafts, pump covers, bearing bushings, and bearing seals. This pump achieves fluid conveyance through the rotation of externally meshed gears. When the volume of the disengaged gear's tooth valley increases, it draws in oil; when the volume of the meshed gear's tooth valley decreases, it discharges oil. Each rotation delivers a constant volume of oil, which is ultimately expelled from the pump body through the discharge port in a continuous manner with minimal pulsation, ensuring stable fluid supply.

Application:

1. It provides power for hydraulic systems, widely applied in various industrial equipment and machinery requiring hydraulic power.

2. This unit serves as a conveying and pressurizing pump for transporting lubricating oils and fuel oils in petrochemical and refining industries.

3. In fuel systems, it functions as a fuel pump for conveying, pressurizing, and injecting fuel, serving fuel supply systems in automobiles, vessels, and other equipment.

4. Used as lubricating oil pumps in metallurgy, mining, power generation, and building materials industries to supply lubricating oil to the lubrication systems of various mechanical equipment.

Feature:

1. This equipment employs advanced technology to ensure uniform fluid flow within the pump body, delivering stable and reliable flow output.

2. To achieve exceptionally low operating noise, it utilizes a unique gear tooth profile design and high-precision machining techniques, creating a quieter and more comfortable working environment.

4. Critical components of the pump body are constructed from premium alloy steel or cast iron, enhanced with specialized heat treatment processes to improve wear resistance and corrosion resistance, thereby extending service life.

Performance Data:

| Model |

Capacity Q |

Pressure |

Power |

Speed |

Inlet/Outlet Diameter |

| m³/h |

L/min |

M pa |

Kw |

r/min |

| 2CY-0.6/2.5 |

0.6 |

10 |

2.5 |

61 |

940 |

G3/4” |

| 2CY-1.08/2.5 |

1.08 |

18 |

1400 |

| 2CY-1.5/2.5 |

1.5 |

25 |

63 |

960 |

G1” |

| 2CY-2.1/2.5 |

2.1 |

35 |

1420 |

| 2CY-3/2.5 |

3 |

50 |

1440 |

| 2CY-4 |

4 |

66 |

0.75 |

65 |

960 |

| 2CY-4.2/2.5 |

4.2 |

70 |

2.5 |

1440 |

G1 1/4” |

| 2CY-5-2.5 |

5 |

83 |

960 |

G1 1/2” |

| 2CY-6-2.5 |

6 |

100 |

67 |

1440 |

| 2CY-7 |

7 |

116 |

0.75 |

63 |

960 |

| 2CY-7.5/2.5 |

7.5 |

125 |

2.5 |

67 |

1440 |

| 2CY-8.5/2.5 |

8 |

135 |

69 |

960 |

G2’ |

| 2CY-12/2.5 |

12 |

200 |

1450 |

| 2CY-18/2.5 |

18 |

300 |

70 |

970 |

80mm |

| 2CY-20/2.5 |

20 |

335 |

1470 |

| 2CY-30/2.5 |

30 |

500 |

1470 |

| 2CY-38/1.0 |

30 |

633 |

1.0 |

72 |

980 |

100mm |

.png)

.png)

.png)

.jpg)

.png)