Summarize:

.jpg)

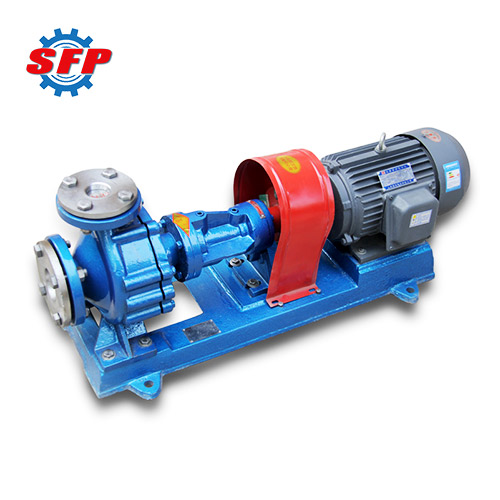

IHF series fluoroplastic centrifugal pump is a single-stage, single-suction centrifugal pump specifically designed for conveying highly corrosive media such as sulfuric acid, acetic acid, hydrochloric acid, nitric acid, strong alkalis, strong oxidizing agents, and organic solvents at any concentration. Due to its stable operation, compact structure, and corrosion resistance, this pump has become an essential piece of equipment in industries such as automobile manufacturing, non-ferrous metal smelting, pesticide production, and wastewater treatment. Additionally, to ensure long-term operation in harsh environments, the pump body is lined with fluoroplastic material, and the pump cover features metal inserts.

Product Details:

IHF series lined fluorine centrifugal pump is manufactured in accordance with international standards and incorporates other advanced production technologies. The pump body features a metal housing lined with PTFE polypropylene, while the pump cover, impeller, and liner are made from metal inserts combined with sintered and pressed fluoroplastic. Additionally, the shaft seal employs an advanced external bellows mechanical seal, with the stationary ring made of 99.9% alumina ceramic (or silicon nitride) and the rotating ring made of PTFE-filled material, offering excellent corrosion resistance and wear resistance.

.png)

Application:

It is available for chemical, pharmaceutical, petroleum, metallurgy, smelting, electric power, electroplating, dyestuff, pesticide, papermaking, food, textile and other industries, conveying strong corrosive liquids such as hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia, strong alkali, strong oxidizing agent, organic solvents, reducing agent and so on.

Feature:

1. It features high strength, wear resistance, high-temperature resistance, and resistance to aging, with an operating temperature range of -20°C to 150°C.

2. This pump employs an external bellows mechanical seal, with the stationary ring made of aluminum oxide ceramic or silicon carbide, and the rotating ring made of PTFE-filled material or silicon carbide.

3. The pump body, impeller, and pump cover of this pump are all made of metal inserts encased in fluoroplastic alloy and formed through compression molding, enabling them to withstand various corrosive media such as strong acids, strong alkalis, and strong oxidizing agents.

Performance Data:

| Model |

Inlet

(mm) |

Out Let

(mm) |

Motor Power

(KW) |

Flow

(m³/h) |

Head

(m) |

| IHF50-32-125 |

50 |

32 |

2.2 |

12.5 |

20 |

| IHF50-32-125A |

50 |

32 |

1.5 |

11 |

16 |

| IHF50-32-160 |

50 |

32 |

4 |

12.5 |

32 |

| IHF50-32-160A |

50 |

32 |

3 |

11.7 |

28 |

| IHF50-32-200 |

50 |

32 |

7.5 |

12.5 |

50 |

| IHF50-32-200A |

50 |

32 |

5.5 |

11.7 |

44 |

| IHF65-50-125 |

65 |

50 |

3 |

25 |

20 |

| IHF65-50-125A |

65 |

50 |

2.2 |

22.3 |

16 |

| IHF65-50-160 |

65 |

50 |

5.5 |

25 |

32 |

| IHF65-50-160A |

65 |

50 |

4 |

23.4 |

28 |

| IHF65-40-200 |

65 |

40 |

11 |

25 |

50 |

| IHF65-40-200A |

65 |

40 |

7.5 |

23.4 |

44 |

| IHF80-65-125 |

80 |

65 |

5.5 |

50 |

20 |

| IHF80-65-125A |

80 |

65 |

4 |

45 |

16 |

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)