Summarize:

.jpg)

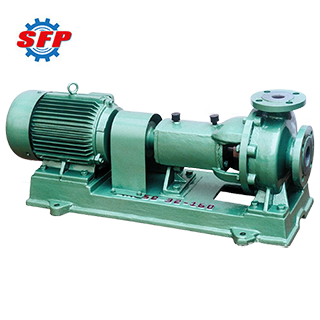

IHF series centrifugal pumps represent a meticulously developed new generation of highly efficient, energy-saving, and highly corrosion-resistant chemical centrifugal pumps. The unique feature of these pumps lies in their flow-through components, which are all manufactured using sintered molded fluoroplastic alloys. This construction provides exceptional chemical corrosion resistance, enabling the pumps to handle virtually all concentrations of corrosive media such as strong acids, strong alkalis, organic solvents, and strong oxidizing agents. Consequently, they are the ideal choice for highly corrosive, leak-prone, and high-pollution operating conditions.

Product Details:

IHF series chemical centrifugal pumps are designed and manufactured in accordance with international standards, incorporating non-metallic pump technology. The pump body features a metal shell lined with PTFE polypropylene material and its pump cover, impeller, and lining are sintered and pressed using metal inserts and fluoroplastic. The shaft seal employs an external high-grade bellows mechanical seal, with the stationary ring made of 99.9% alumina ceramic (or silicon nitride) and the rotating ring using PTFE packing. This configuration delivers exceptional corrosion resistance and wear resistance.

.png)

Application:

It is applicable to industries such as chemical engineering, pharmaceuticals, petroleum, metallurgy, smelting, power generation, electroplating, dyes, pesticides, papermaking, food processing, and textiles. It is designed for conveying highly corrosive liquids like hydrochloric acid, hydrofluoric acid, nitric acid, and aqua regia, as well as strong alkalis, strong oxidizing agents, organic solvents, and reducing agents.

Feature:

1. The shaft seal employs an advanced externally mounted bellows mechanical seal. The grinding moving ring and stationary ring utilize world-leading SSIC industrial ceramics, with alternative grinding materials available upon request for specific operating conditions.

2. This equipment is designed and manufactured in strict compliance with international standards. Its performance metrics, rated operating parameters, and dimensions meet all relevant international and national standards.

3. The body and end covers feature a metal substrate lined with fluoroplastic. The impeller is formed using a special mold with fluoroplastic alloy over a metal insert.

Performance Data:

| Type |

Inlet

(mm) |

Out Let

(mm) |

Motor Power

(KW) |

Flow

(m³/h) |

Head

(m) |

| IHF50-32-125 |

50 |

32 |

2.2 |

12.5 |

20 |

| IHF50-32-125A |

50 |

32 |

1.5 |

11 |

16 |

| IHF50-32-160 |

50 |

32 |

4 |

12.5 |

32 |

| IHF50-32-160A |

50 |

32 |

3 |

11.7 |

28 |

| IHF50-32-200 |

50 |

32 |

7.5 |

12.5 |

50 |

| IHF50-32-200A |

50 |

32 |

5.5 |

11.7 |

44 |

| IHF65-50-125 |

65 |

50 |

3 |

25 |

20 |

| IHF65-50-125A |

65 |

50 |

2.2 |

22.3 |

16 |

| IHF65-50-160 |

65 |

50 |

5.5 |

25 |

32 |

| IHF65-50-160A |

65 |

50 |

4 |

23.4 |

28 |

| IHF65-40-200 |

65 |

40 |

11 |

25 |

50 |

| IHF65-40-200A |

65 |

40 |

7.5 |

23.4 |

44 |

| IHF80-65-125 |

80 |

65 |

5.5 |

50 |

20 |

| IHF80-65-125A |

80 |

65 |

4 |

45 |

16 |

.jpg)

.png)