.jpg)

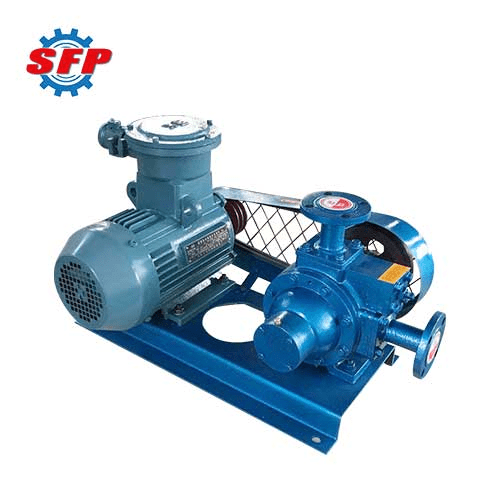

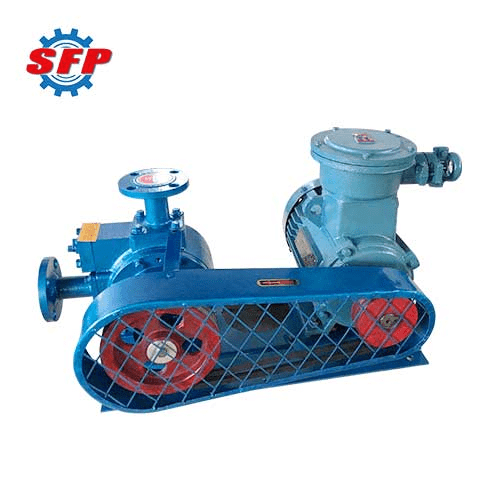

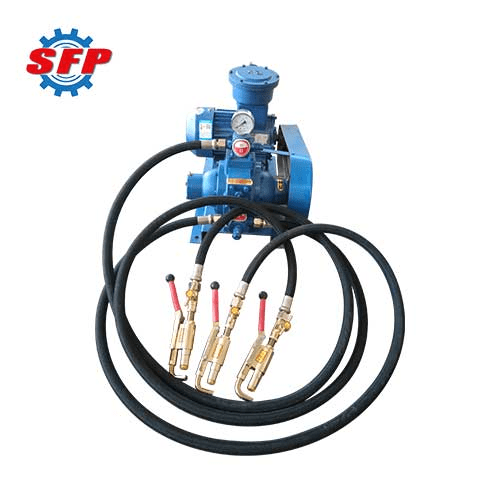

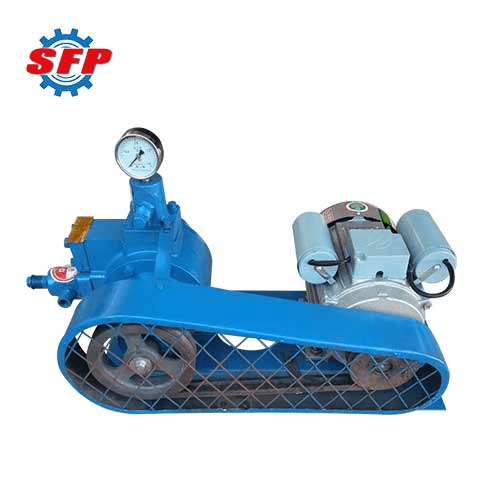

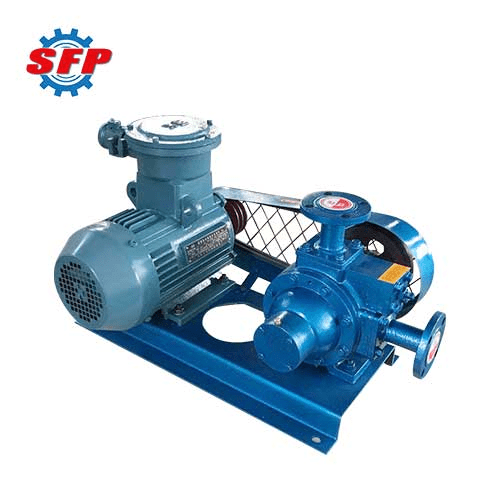

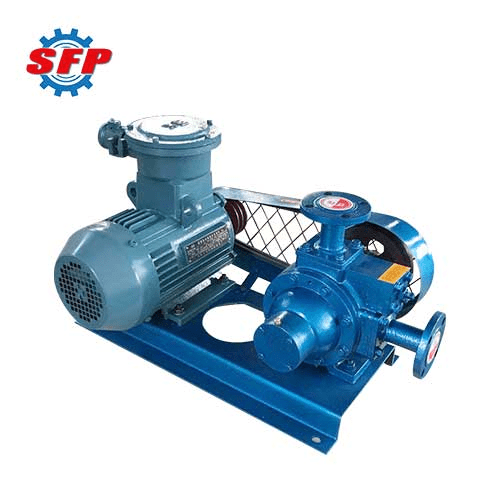

LPG gas filling pump is availablee for delivering liquefied petroleum gas, dimethyl ether, methyl chloride, ethylene oxide, propane, butadiene, isobutylene, methanol and other gases. It can also be used in LPG loading and unloading trucks, charging workshops, automobile fuel filling and other places. Moreover, this product adopts advanced technology and design, has the characteristics of high efficiency and energy saving, and can effectively reduce energy consumption and operating costs.

Liquefied petroleum gas (LPG) refueling pumps are positive displacement vane pumps that operate on the principle of centrifugal sliding vanes. When the rotor rotates, the volume of the inlet chamber gradually increases, creating negative pressure and suction, thereby drawing in liquid. As the rotor continues to rotate to a certain angle, the volume gradually decreases, thereby expelling the liquid.

.png)

| Model | Speed (r.p.m) |

Flow (m³/h) |

Pressure Difference (MPa) |

Working Pressure (MPa) |

Power (kW) |

Inlet Size (inch) |

Outlet Size (inch) |

Temperature Range (℃) |

| YQB2-5 | 600 | 2 | 0.5 | 1.6 | 1.5 | 1 | 1 | +40 -40 |

| YQB5-5 | 780 | 5 | 2.2 | 1.2 | 1.2 | |||

| YQB10-5 | 600 | 10 | 0.5 | 1.6 | 5.5 | 2 | 2 | +40 -40 |

| YQB15-5 | 780 | 15 | ||||||

| YQB15-5A | 780 | 15 | 0.4 | 1.6 | 4 | 2 | 2 | +40 -40 |

| YQB10-5A | 600 | 10 | ||||||

| YQB25-5 | 600 | 25 | 0.5 | 1.6 | 11 | 3 | 3 | +40 -40 |

| YQB35-5 | 780 | 35 | ||||||

| YQB50-5 | 600 | 50 | 0.5 | 1.6 | 15 | 4 | 4 | +40 -40 |

| YQB60-5 | 780 | 60 | 0.5 | 1.6 | 15 | 4 | 4 | +40 -40 |

| YQB80-5 | 780 | 80 | 0.5 | 1.6 | 18.5 | 4 | 4 | +40 -40 |