.jpg)

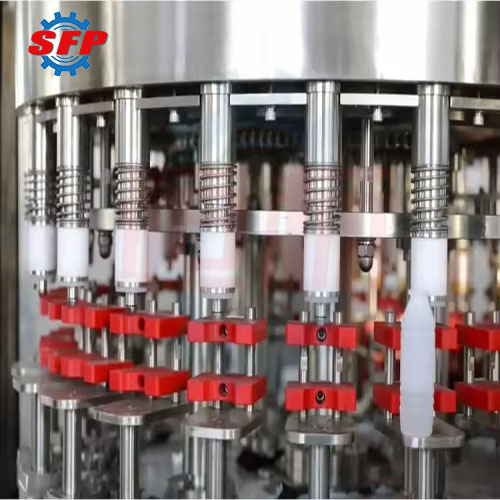

Automatic dairy bottle filling machine is designed for filling PP or PE bottled drinks, suitable for milk drinks, tea drinks, energy drinks and other liquids. If you need to fill pure water or mineral water, you only need to replace a few spare parts on the milk filling machine. Therefore, this machine is suitable for food, beverage, dairy, pharmaceutical and other industries. The product is characterized by reasonable design, simple structure, quantitative filling, convenient operation, robustness and durability, clean maintenance and so on.

Automatic dairy bottle filling machine integrates transportation, filling, cleaning, sealing, and capping processes into a single unit, effortlessly accommodating various bottle shapes while significantly reducing auxiliary equipment requirements and simplifying filling operations. To achieve faster, more stable filling without compromising precision, we employ advanced micro-pressure technology. The cleaning system rotates empty bottles 180 degrees via conveyor tracks, enabling simultaneous internal and external cleaning to ensure optimal bottle cleanliness.

.png)

| Model | SGF12125 | SGF18186 | SGF24248 | SGF323210 | SGF404012 | SGF505012 |

| Washing/Filling/Capping Heads | 12-12-5 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 |

| Production Capacity (B/H) | 2000-4000 | 5000-7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 |

| Motor Power(kw) | 2.2kw | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 |