Summarize:

.jpg)

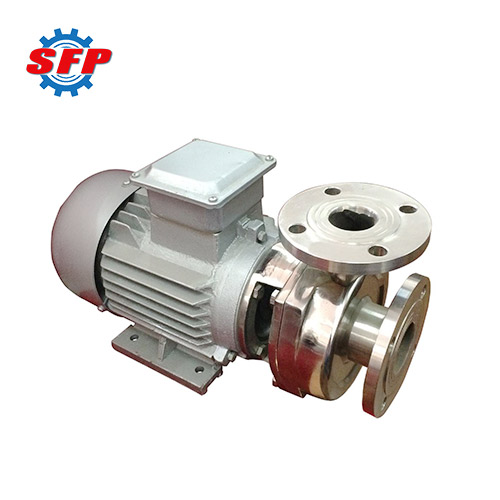

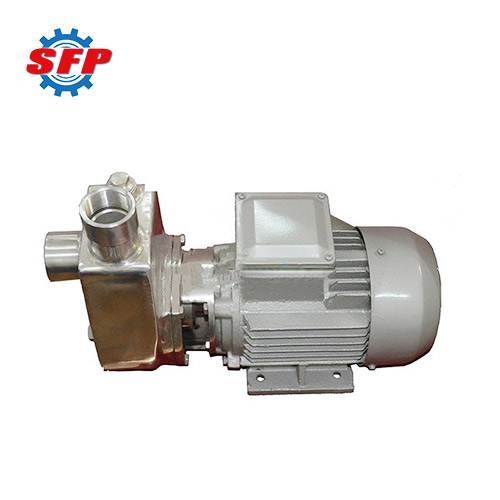

SFBX series corrosion resistant centrifugal pumps combine excellent structure, performance and appearance with advanced cantilever technology and mechanical seals for shaft sealing. Meanwhile, in order to ensure efficient and smooth conveying of media, the pump's overflow parts and connecting frame are made of high quality and durable materials. With its advantages of corrosion resistance, easy use and maintenance, compact structure, low energy consumption and good sealing performance, the pump is the best equipment for conveying corrosive liquids with fine and soft particles in sewage treatment, cosmetic, chemical, electroplating and other industries.

Product Details:

SFBX series chemical centrifugal pump is composed of impeller, pump body, mechanical seal, motor and bearing bracket. When the impeller rotates, the liquid will be thrown to the impeller under the action of centrifugal force, and a vacuum zone will be formed at the center of the impeller. The liquid discharged from the impeller passes through a pressurized chamber and is then transported out along the discharge line. Thus, the impeller rotates continuously, thus continuously drawing in and discharging liquid.

Application:

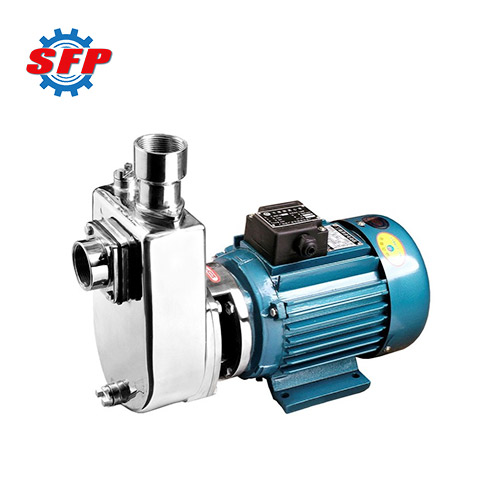

It can transport liquids with a temperature not higher than 90℃ (direct connection type) or not higher than 105℃ (with bearing bracket type) with small soft particles or fibrous, corrosive or sanitary requirements. This machine has self-priming performance and is widely used in food, beverage, medicine, sewage treatment, chemical, electroplating, bleaching and dyeing, fine chemical and other industries.

(1).png)

Feature:

1. The pump's flow-through parts and connecting frames are made of high quality and durable materials, such as 1Cr18Ni9Ti, 304, 316L, etc. The static ring of the mechanical seal is made of ceramic (SiC). The static ring of the mechanical seal is made of ceramic (SiC) and the rubber structural parts are made of fluorine rubber with good corrosion resistance.

2. The connection between impeller pump and motor includes direct connection type and bearing bracket type, which can meet the requirements of different working conditions.

3. SFBX series pumps have self-priming function, which can solve the problem of suction range to a certain extent and is convenient to use.

4. Its shaft seal adopts cantilever mechanical seal, which is reliable and can effectively prevent medium leakage.

Parameter Data:

Model

(Three-phase

/380V

/50Hz) |

Model

(single-phase

/380V

/50Hz) |

Power

(kW) |

Inlet

(mm) |

Outlet

(mm) |

Efficiency

(%) |

H: Head(m)

Q: Flow(m³/h) |

NPSH

(m) |

| 25SFBX-8 |

25SFBX-8D |

0.25 |

25 |

25 |

40 |

H |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

|

|

5.5 |

| Q |

2.3 |

3 |

3.5 |

4.3 |

4.8 |

5.2 |

5.5 |

|

|

| 25SFBX-13 |

25SFBX-13D |

0.55 |

25 |

25 |

40 |

H |

16 |

15 |

14 |

13 |

12 |

10 |

8 |

6 |

4 |

4 |

| Q |

3 |

4 |

4.8 |

6 |

6.5 |

7.5 |

8.5 |

9.5 |

10 |

| 40SFBX-18 |

40SFBX-18D |

1.5 |

40 |

40 |

49 |

H |

21 |

20 |

19 |

18 |

16 |

14 |

12 |

10 |

8 |

4 |

| Q |

6 |

7 |

8.5 |

10 |

12 |

14 |

15.5 |

17.3 |

18.5 |

| 50SFBX-22 |

|

3 |

50 |

50 |

50 |

H |

28 |

26 |

25 |

24 |

22 |

20 |

18 |

16 |

14 |

4 |

| Q |

8.5 |

11.5 |

13.5 |

14.5 |

16.5 |

19 |

20.5 |

22 |

23.8 |

.jpg)

(1).png)