Summarize:

.jpg)

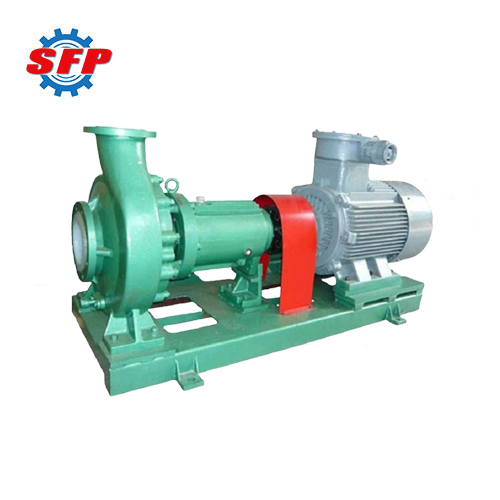

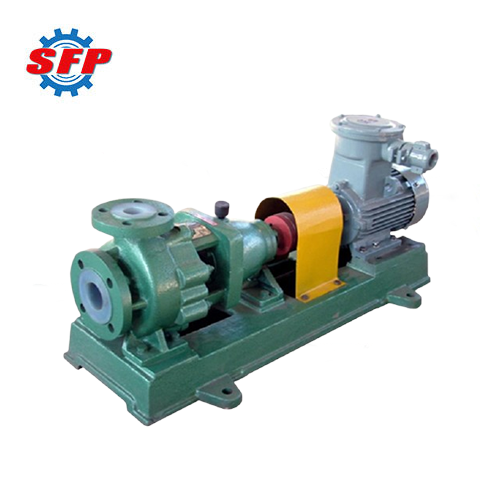

IHF series fluoroplastic centrifugal pumps are suitable for conveying strong corrosive media such as sulfuric acid, hydrochloric acid, acetic acid, strong alkali, nitric acid, strong oxidising agents, organic solvents and so on in any concentration. It can be used in automobile manufacturing, non-ferrous metal smelting, pesticide manufacturing, waste water treatment and other industries. The pump body is made of fluoroplastic lining material, and the pump cover is made of metal inserts, so it can be operated for a long time in the harsh environment.

Product Details:

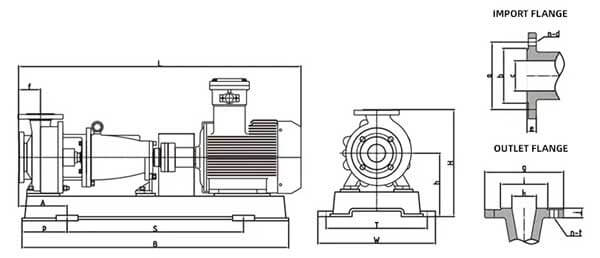

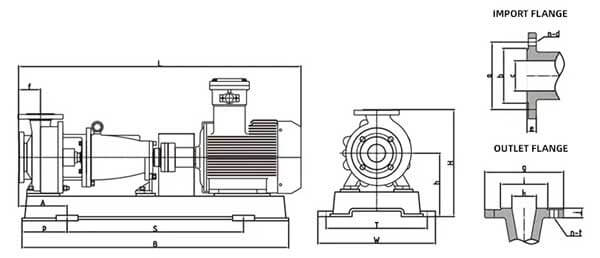

IHF fluoroplastic acid centrifugal pump is designed and manufactured in accordance with international standards and combined with non-metallic pump technology. The pump body adopts metal shell lined with PTFE propylene, and the pump cover, impeller and liner plate are sintered and pressed with metal inserts and fluoroplastic. Meanwhile, the shaft seal adopts external advanced bellows mechanical seal, the static ring adopts 99.9% alumina ceramics (or silicon nitride), and the dynamic ring adopts PTFE filling material, which has excellent corrosion resistance and wear resistance.

Application:

It is suitable for conveying hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia, strong alkali, strong oxidizing agent, organic solvent, reducing agent and other strong corrosive liquids in the industries of chemical industry, pharmaceutical industry, petroleum industry, metallurgy industry, smelting industry, electric power industry, electroplating industry, dyestuff industry, pesticide industry, papermaking industry, foodstuff industry, textile industry and so on.

1. Electrolyte transportation in non-ferrous metal smelting.

2. Pickling and painting process in automobile manufacturing and iron and steel industry.

3. Chlorine water, wastewater treatment and acid addition in ionic membrane caustic soda project in steel and automobile manufacturing industry.

Feature:

1. The shaft seal adopts advanced externally mounted bellows mechanical seal, and the grinding dynamic and static rings are made of world advanced SSIC industrial ceramics, and other materials can also be used to grind materials according to the user's special working conditions.

2. It is designed and manufactured in accordance with international standards, so that its performance, rated performance points and dimensions are equivalent to the relevant international and national standards.

3. The body and cover are made of metal matrix lined with fluoroplastic, and the impeller is formed on metal inserts by special molds of fluoroplastic alloy.

Performance Data:

| Type |

Inlet

mm |

Out Let

mm |

Motor Power

KW |

Flow

m3/h |

Head

m |

| IHF50-32-125 |

50 |

32 |

2.2 |

12.5 |

20 |

| IHF50-32-125A |

50 |

32 |

1.5 |

11 |

16 |

| IHF50-32-160 |

50 |

32 |

4 |

12.5 |

32 |

| IHF50-32-160A |

50 |

32 |

3 |

11.7 |

28 |

| IHF50-32-200 |

50 |

32 |

7.5 |

12.5 |

50 |

| IHF50-32-200A |

50 |

32 |

5.5 |

11.7 |

44 |

| IHF65-50-125 |

65 |

50 |

3 |

25 |

20 |

| IHF65-50-125A |

65 |

50 |

2.2 |

22.3 |

16 |

| IHF65-50-160 |

65 |

50 |

5.5 |

25 |

32 |

| IHF65-50-160A |

65 |

50 |

4 |

23.4 |

28 |

| IHF65-40-200 |

65 |

40 |

11 |

25 |

50 |

| IHF65-40-200A |

65 |

40 |

7.5 |

23.4 |

44 |

| IHF80-65-125 |

80 |

65 |

5.5 |

50 |

20 |

| IHF80-65-125A |

80 |

65 |

4 |

45 |

16 |

.png)

.png)

.png)

.png)

.jpg)

.png)