Summarize:

.jpg)

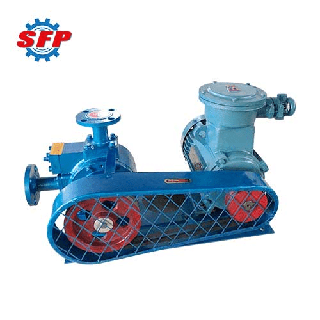

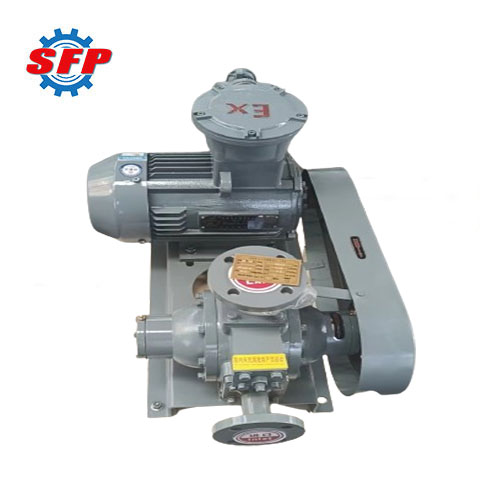

LPG gas transfer pump is commonly applied to deliver liquefied petroleum gas, propylene, liquid ammonia, ethylene oxide, methanol, various volatile liquids or petroleum products with similar properties. The equipment can be used in workplaces such as gas cylinder filling, liquefied petroleum gas loading and unloading vehicles, and gas filling workshops. In order to ensure the safety and reliability of the pump when delivering flammable and explosive media such as liquefied petroleum gas, the equipment adopts advanced structural design and high-quality sealing materials.

Product Details:

LPG gas filling pump works by centrifugal sliding of the blade, and the flow rate is related to the rotation speed of the shaft. The curved surface is made of the original composite curve, which is composed of a stator and a rotor, a baffle plate and a blade, and the ten sealing cavity is composed of a stator and a rotor. The surface of the stator is a composite curve, when the rotor rotates, the volume of the inlet cavity increases gradually, and the negative pressure is formed. To suck oil into. When the rotor is rotated to a certain angle, the volume section is gradually reduced, thus the oil hydraulic pressure is reduced. Between the oil suction chamber and the pressure oil chamber, an oil block is arranged between the oil suction cavity and the oil pressure cavity. Thus, the surface of the stator is tightly combined with the inner surface of the pump, so that the pump can work normally under the rated condition.

Application:

LPG gas pumps are mainly applied to transport various volatile liquids and petroleum products with similar properties, including liquefied petroleum gas, dimethyl ether, methyl chloride, ethylene oxide, propane, propylene, butadiene, isobutylene, methanol, etc. It is also suitable for liquefied petroleum gas truck loading and unloading, cylinder filling, workshop gas filling and other operating occasions.

Feature:

1. It can be equipped with a belt drive system for easier maintenance, inspection, and operation.

2. The motor enables precise adjustment, effectively reducing vibration and ensuring smooth operation.

3. The pump's internal rotating components feature a metal-nonmetal composite structure, effectively preventing static electricity generation.

Performance Data:

| Model |

Speed |

Flow |

Pressure Difference |

Working Pressure |

Power |

Temperature |

|

| YQB2-5 |

600r.P.m |

2 m³/h |

1.8MPa

0.5MPa |

2.0MPa |

1.5KW |

-40 ~40℃ |

|

| YQB5-5 |

780r.P.m |

5 m³/h |

2.0MPa |

2.2KW |

-40 ~40℃ |

|

| YQB10-5 |

600r.P.m |

10 m³/h |

1.8MPa |

5.5KW |

-40 ~40℃ |

|

| YQB15-5 |

780r.P.m |

15 m³/h |

1.8MPa |

5.5KW |

-40 ~40℃ |

|

| YQB25-5 |

600r.P.m |

25 m³/h |

1.8MPa |

11KW |

-40 ~40℃ |

|

| YQB35-5 |

780r.P.m |

35 m³/h |

1.8MPa |

11KW |

-40 ~40℃ |

|

| YQB50-5 |

780r.P.m |

50 m³/h |

1.8MPa |

15KW |

-40 ~40℃ |

|

| YQB80-5 |

780r.P.m |

80 m³/h |

1.8MPa |

18KW |

-40 ~40℃ |

|

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)